Sustainability

Pioneering Sustainable Manufacturing in Sri Lankan Rubber Industry

For over three decades, we have been committed to a harmonious relationship between community and environment. Long before the trend of sustainable manufacturing gathered pace around the world, we drew inspiration from the magnificent landscape surrounding us to develop a sustainable manufacturing philosophy based on sustainable development principles.

Built upon the commitment outlined in our Sustainability principles, our Sustainability Strategy promote a holistic framework of initiatives that focus on the environment, economy and people both within and beyond our company. Our sustainable strategy focuses on five key categories.

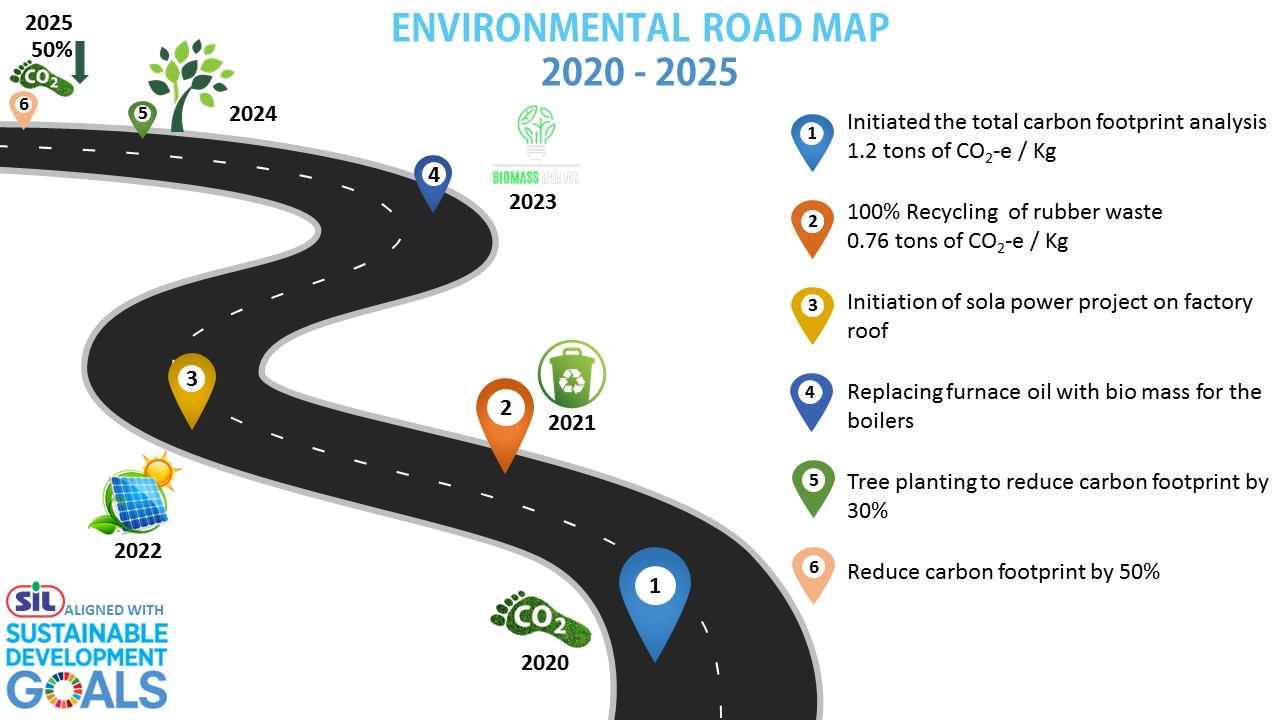

Energy & Carbon

We play an active role in the global fight against climate change by striving towards reducing our carbon footprint by effective energy management and reducing the amount of carbon emission. Therefore, we have obtained ISO 50001:2018 certification to ensure effective energy management practices are flowed in our production facilities. Further we have covered all our roof tops with solar panels which will contribute approximately 100MW of electricity to the national grid annually.

We are committed to;

- Improve our energy performance through continues reduction in energy consumption.

- Managing energy performance through design and modification of our facilities, procurement of energy efficient equipment and upgrades to our systems & processes.

- Allocate resources and provide necessary information to achieve energy objectives and targets.

- Retain employees’ commitment towards energy conservation.

- Organize products and services effectively to utilize energy in an efficient manner.

- Compiling to all legal and energy related other requirements.

- Ensuring the documentation and communication of our energy policy to all personnel in the organization while its contents are appropriately understood and committed towards achieving the set goals.

Waste & Water Management

We adopt the 3R method of Reduce- Reuse- Recycle at all our factories. Our waste rubber is recycled and supplied to another sister Company to manufacture reclaimed rubber products. Solid waste generated from our operations are segregated at source and disposed with minimal environmental damage. Further the water used in the factory is treated at our in-house water treatment facility and is been reused for gardening and cooling purposes. We persistently monitor the quality of the water discharged from our operations, to ensure it to be within the parameters specified by the Central Environmental Authority.

Employees & Community

We take our employees wellbeing seriously. We are the proud recipient of “BSCI-Grade A” certification from the Business Social Compliance Initiative (BSCI) which is the highest possible rating under this category. This is a testament to SILs commitment towards the level of care towards its employees in terms of benefits, quality of life, environmental conditions, safety etc…

We also continue to be committed to contributing to the national economy by serving to rural areas in the Southern Province and using local raw materials. Out of our total raw materials cost, 60% is from rubber which comes from the plantations in the Southern Province, providing direct employment opportunities to many locales.

Environment

Environment has always been one of our top priorities. We have obtained ISO 14001:2015 certification for environmental management to ensure that we fallow best environmental practices at every stage of our production process. We are also the first rubber product manufacturer in Sri Lanka to produce FSCTM (FSCTM C134777) certified rubber products.

At SIL we strive to meet all compliance obligations related to environment by incorporating good environmental practices into our decisions and operations with the highest dedication of the management and the employees.

We acknowledge the need for responsible and sustainable resource use to improve energy efficiency, reduction of waste, pollution of air, water and land contamination by developing a dedicated organizational culture through awareness and training. Moreover, we strive to ensure the continual improvement towards achieving our environmental objectives.

Further, we ensure that our environmental policy is documented, implemented, maintained and communicated to all the employees of our organization and is available to all the interested parties on request.

Sourcing & Production

The involvement of local communities is a defining trait of SIL which we strictly adhere to. Certain functions of our production process is outsourced to local community which provide many direct and indirect employment opportunities. Our production process is managed by ISO 9001:2015 quality management system to ensure the responsible use of materials while supplying best quality products to our customers. Further our products have a very high local value addition as we try to source most of our row materials locally.